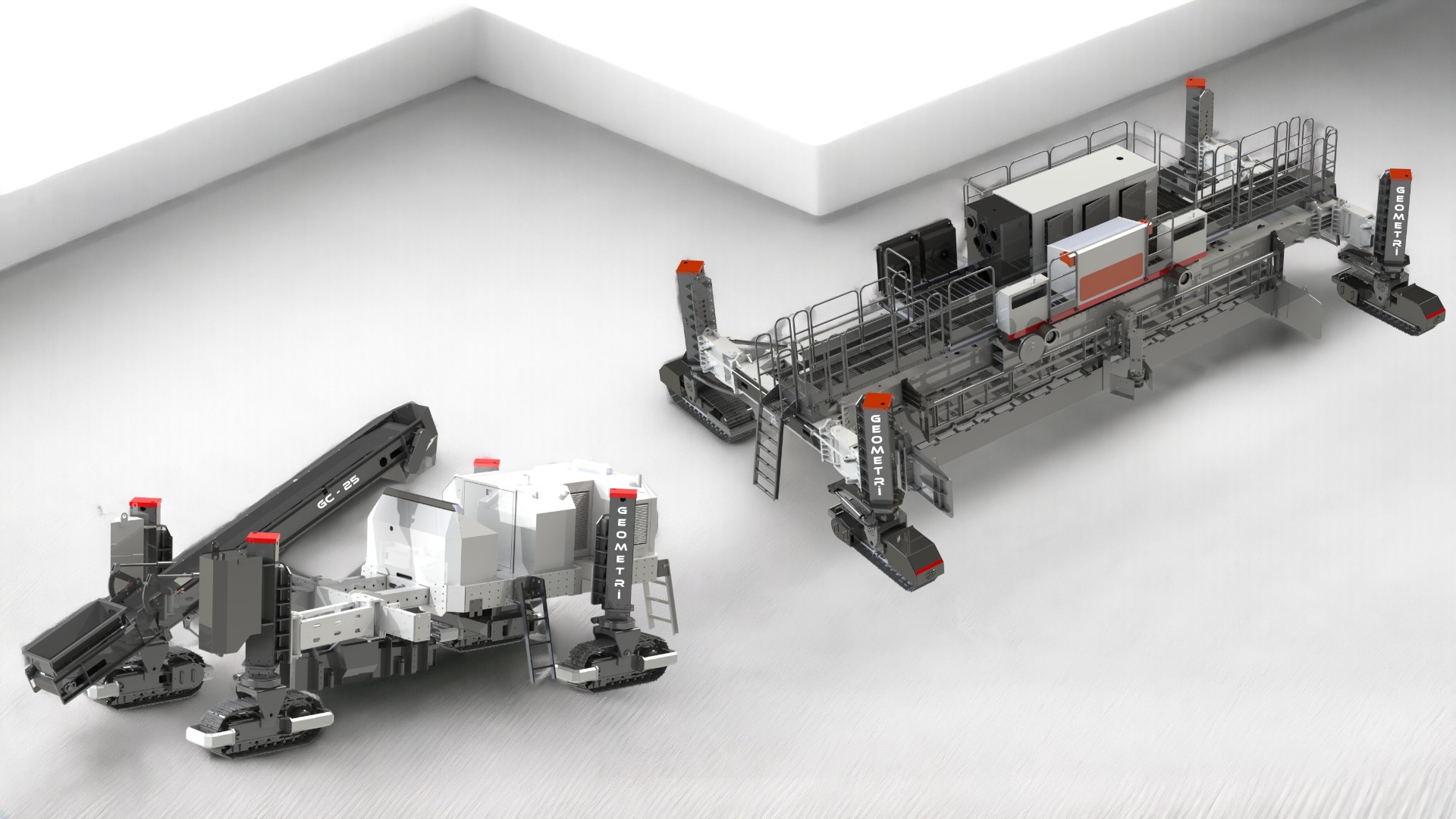

Offset paving machines specialize in crafting continuous concrete structures like safety barriers, curb designs, drainage channels, or walkways. Their adaptability is enhanced by a variety of configurations for concrete delivery or slipform techniques. Conversely, inset paving machines are designed for economical construction of concrete roadways, including highways, main thoroughfares, airstrips, or train tracks. They’re also capable of simultaneously laying a base and a surface layer of concrete in a ‘wet on wet’ method, beyond just single-layer paving.

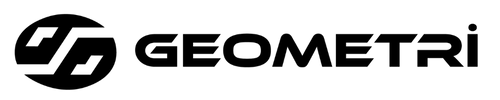

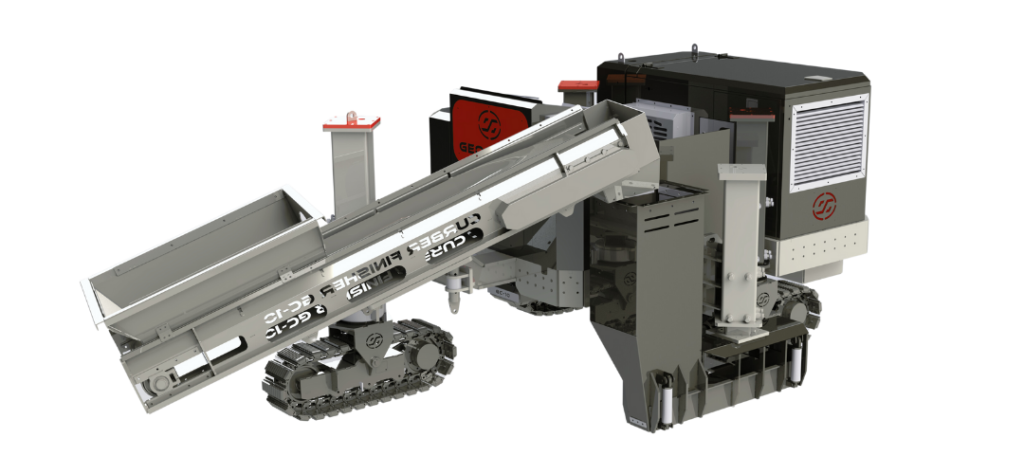

Offset slipform pavers transfer concrete into the mold using a loader conveyor or a auger. The mold can be positioned on either the left or right side of the machine, offering flexibility in operation. A diverse array of molds is available, catering to various shapes and sizes for specific tasks. These machines continuously create monolithic offset profiles, which can be reinforced or not, depending on the requirement. Key features of these machines include a sophisticated control system, an efficient steering and driving mechanism, and the capability for stringless concrete paving.

Offset slipform pavers

Max. mould width

1000 mm

Max. mould height

500 mm

Rated power

45,5 kW / 61 HP

Operating weight, CE

5400 kg

Offset slipform pavers

Max. mould width

3000 mm

Max. mould height

1300 mm

Rated power

134,3 kW / 180 HP

Operating weight, CE

10500 kg

Offset slipform pavers

Max. mould width

5500 mm

Max. mould height

2000 mm

Rated power

134,3 kW / 180 HP

Operating weight, CE

16500 kg

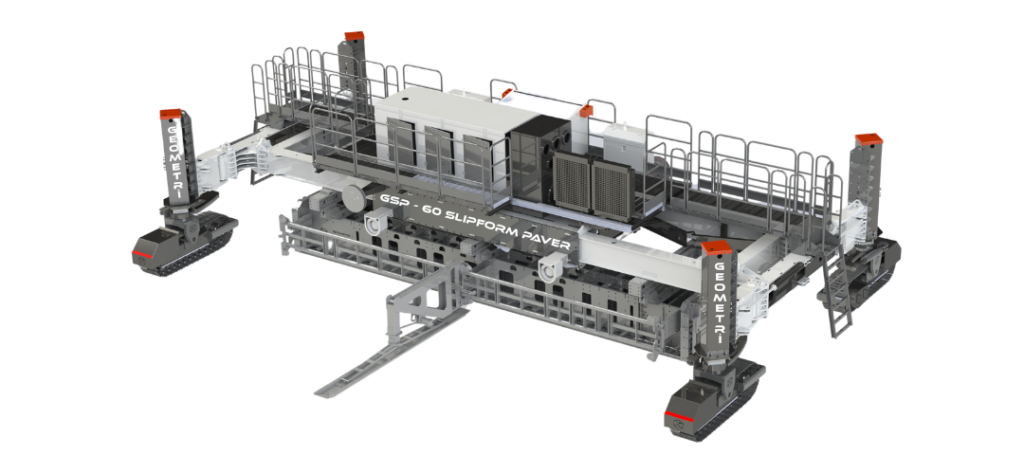

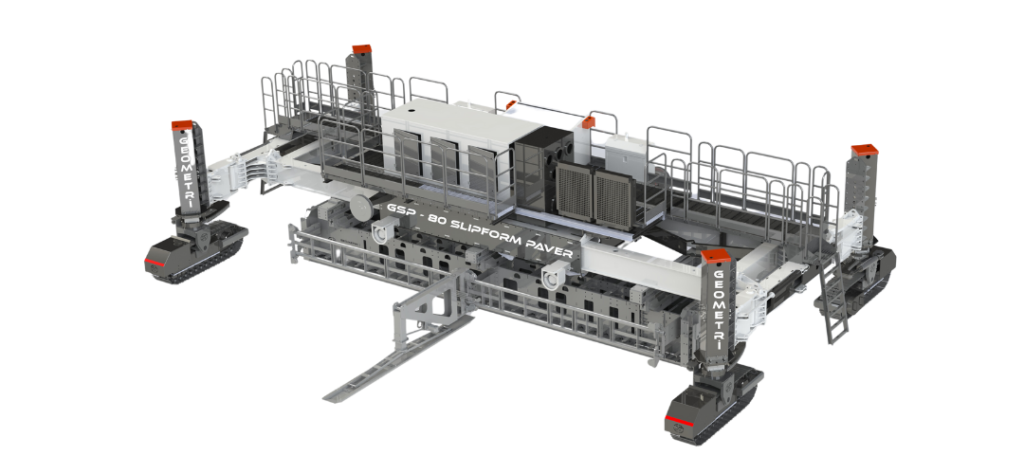

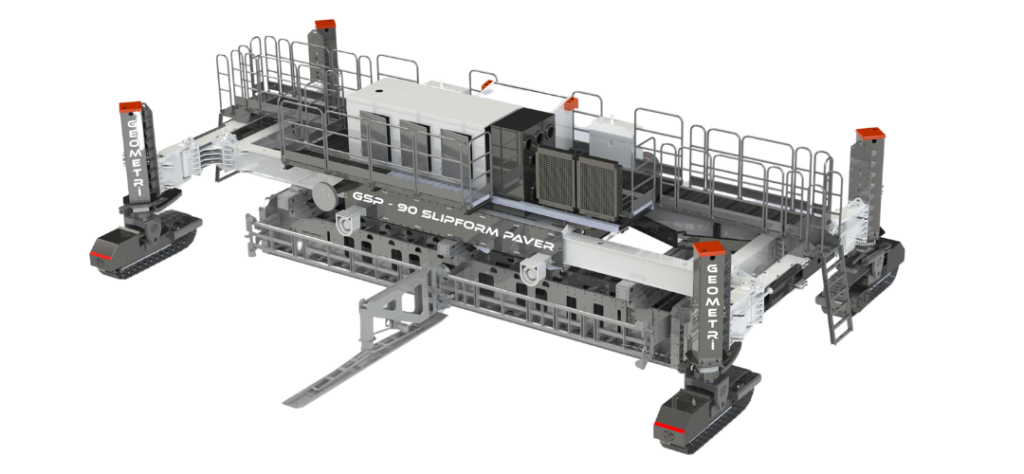

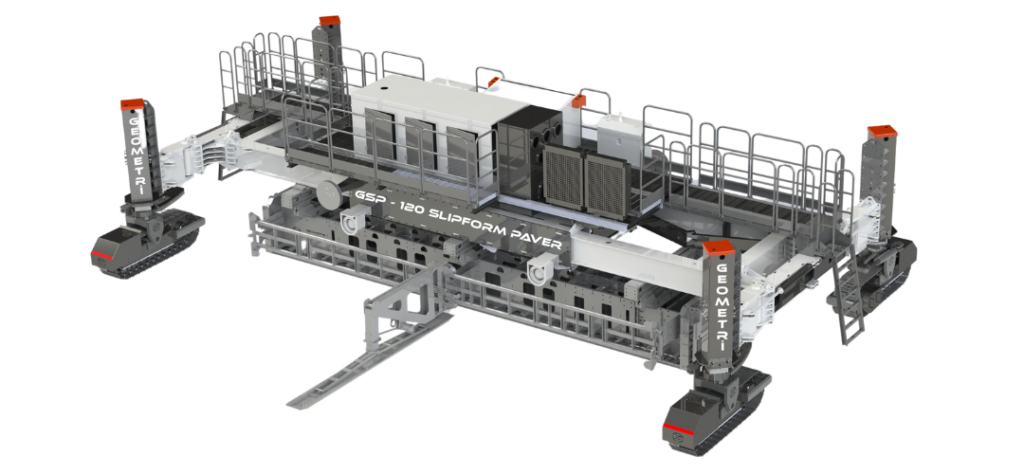

In the process of inset slipform paving, the concrete is directly deposited ahead of the paver and evenly spread by either an auger or a plough. The concrete is uniformly compacted by vibrators, while the mold shapes it to the pre-set width and depth as the machine progresses. Dowel bars and tie bars are accurately placed by integrated inserters. A finishing beam smooths the pavement transversely, and a super smoother ensures the surface is flawlessly finished. In dual-layer concrete paving, both the lower and upper layers are laid and processed together, using the wet-on-wet technique.

Inset slipform pavers

Concrete Width

1000-6000 mm

Number of Vibrators

20

Engine Power

194 kW / 260 HP

Concrete Thickness

0-450mm

Weight

26000 kg

Inset slipform pavers

Concrete Width

1000-8000 mm

Number of Vibrators

24

Engine Power

223,9 kW / 300 HP

Concrete Thickness

0-450mm

Weight

40000 kg

Inset slipform pavers

Concrete Width

4000-9000 mm

Number of Vibrators

27

Engine Power

298,5 kW / 400 HP

Concrete Thickness

0-450mm

Weight

48000 kg

Inset slipform pavers

Concrete Width

4000-12000 mm

Number of Vibrators

32

Engine Power

343,3 kW / 460 HP

Concrete Thickness

0-450mm

Weight

55000 kg

It is used for concrete laying in working areas such as water canals, concrete profiles, irrigation canals, drainage canals. The concrete mixer discharges the concrete inside the conveyor of the paver. The concrete transferred from the conveyor to the auger which is evenly distributed on each side of the mold. With the help of the vibrators inserted in the mold, the concrete is compressed homogeneously and laid with a sliding mold and plate.

Canal Full Section Slipform Concrete Pavers

Concrete Width

1000-4000 mm

Number of Vibrators

12

Engine Power

156,7 kW / 210 hp

Concrete Thickness

0-450mm

Weight

20000 kg

Canal Full Section Slipform Concrete Pavers

Concrete Width

1000-6000 mm

Number of Vibrators

20

Engine Power

194 kW / 260 hp

Concrete Thickness

0-450mm

Weight

32000 kg

Canal Full Section Slipform Concrete Pavers

Concrete Width

4000-8000 mm

Number of Vibrators

24

Engine Power

223,9 kW / 300 hp

Concrete Thickness

0-450mm

Weight

45000 kg

Canal Full Section Slipform Concrete Pavers

Concrete Width

4000-9000 mm

Number of Vibrators

27

Engine Power

298,5 kW / 400 hp

Concrete Thickness

0-450mm

Weight

52000 kg

Canal Full Section Slipform Concrete Pavers

Concrete Width

4000-12000 mm

Number of Vibrators

32

Engine Power

343,3 kW / 460 hp

Concrete Thickness

0-450mm

Weight

62000 kg

Canal Full Section Slipform Concrete Pavers

Concrete Width

4000-18000 mm

Number of Vibrators

36

Engine Power

373,1 kW / 500 hp

Concrete Thickness

0-450mm

Weight

72000 kg

It is used for concrete laying in working areas such as water canals, concrete profiles, irrigation canals, drainage canals. The concrete mixer discharges the concrete inside the conveyor of the paver. The concrete transferred from the conveyor to the auger which is evenly distributed on each side of the mold. With the help of the vibrators inserted in the mold, the concrete is compressed homogeneously and laid with a sliding mold and plate.

Half Section Slipform Concrete Pavers

Concrete Width

1000-6000 mm

Number of Vibrators

20

Engine Power

194 kW / 260 hp

Concrete Thickness

0-450mm

Weight

30000 kg

Half Section Slipform Concrete Pavers

Concrete Width

4000-8000 mm

Number of Vibrators

24

Engine Power

223,9 kW / 300 hp

Concrete Thickness

0-450mm

Weight

42000 kg

Half Section Slipform Concrete Pavers

Concrete Width

4000-9000 mm

Number of Vibrators

27

Engine Power

298,5 kW / 400 hp

Concrete Thickness

0-450mm

Weight

48000 kg