The Most Profitable in its Sector

EU Stage 3 /

US EPA Tier 3f

1000-9000

mm

0-450

mm

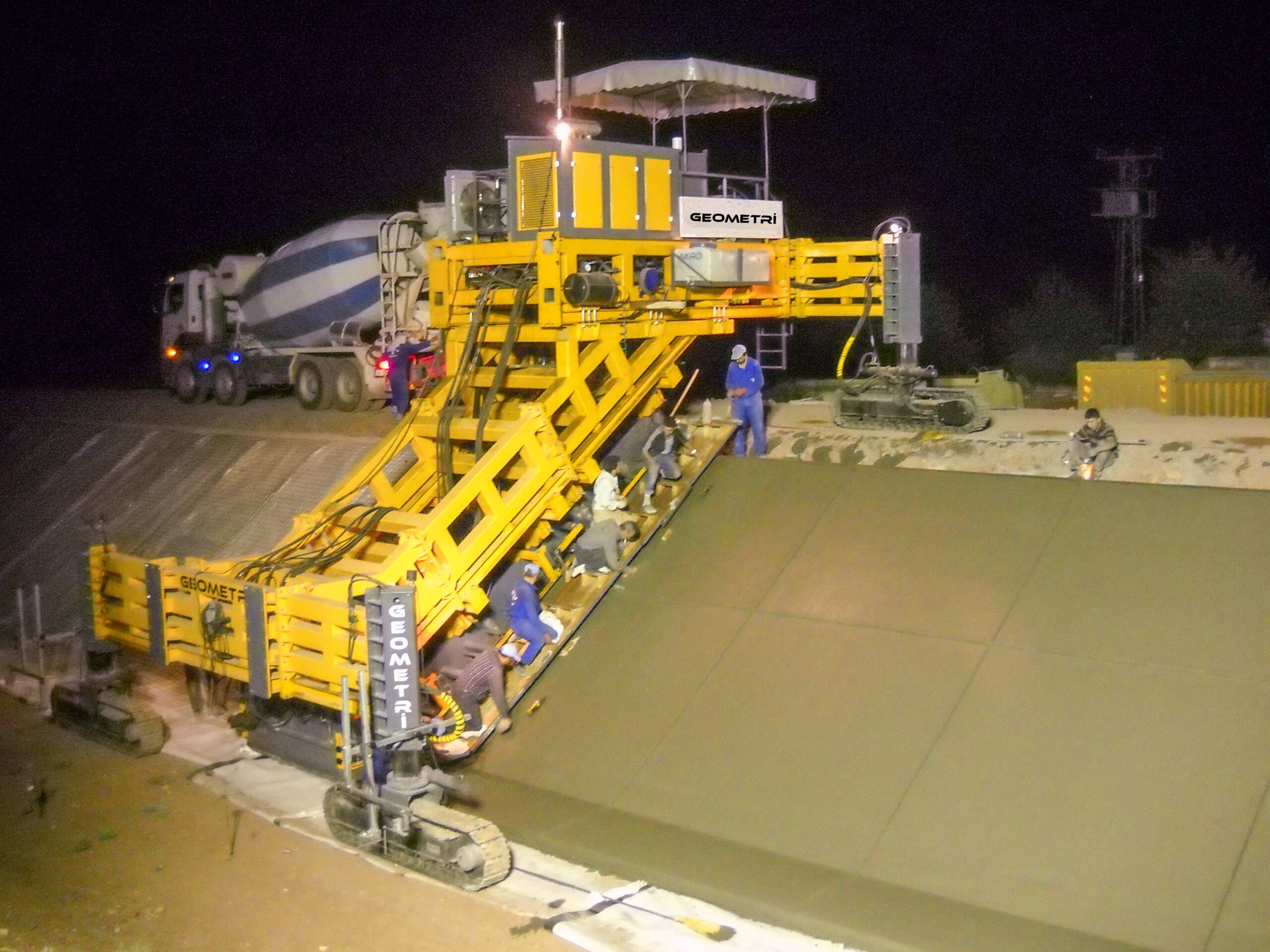

First, our team of concrete paving specialists will study the submitted plans for your waterway project and analyze your equipment needs. This involves top widths, bottom widths, percentage of slope on the walls, is the slope constant throughout the project, top to bottom length of the canal walls, distance of the canals, the number of variations in the profiles, the presence of a haul road and berm, and anticipated concret supply to the paver.

The team will break down the concepts and provide practical recommendations on the choice of slipform concrete paver and mold considerations or paving with a cylinder f inisher machine. The project analysis will include the capability to build in versatility to the equipment to accommodate more than one profile. The biggest advantage you have with your GEOMETRI team is their extensive global experience in canals and waterways.

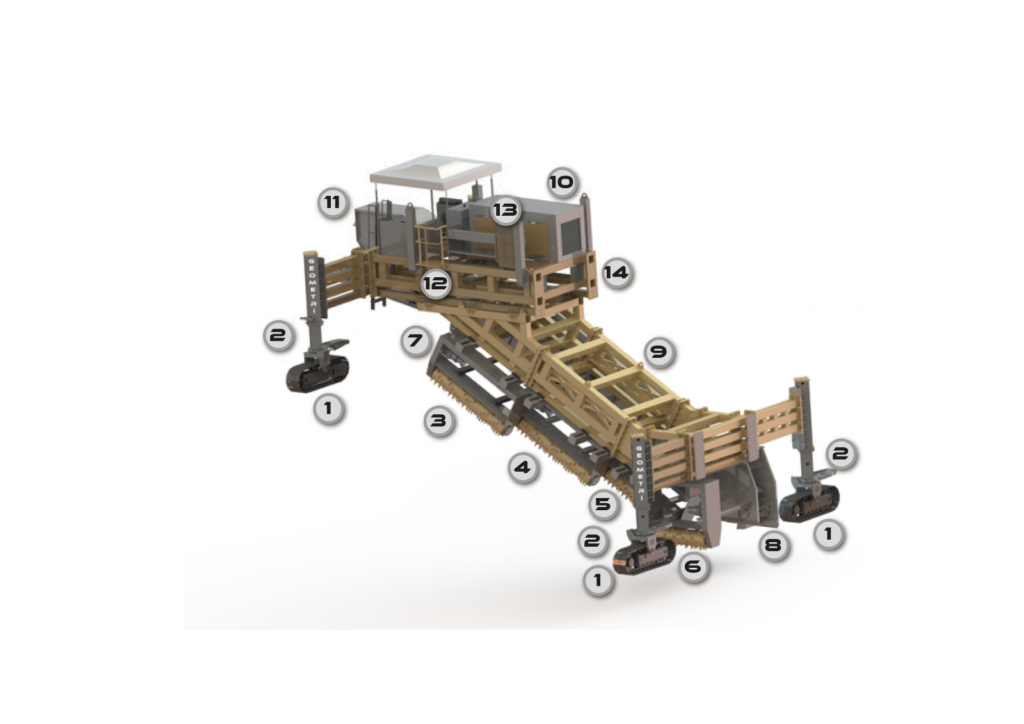

Exhaust emissions category

EU Stage 3 / US Tier 3

Number of track units

4

Paving width

1000 – 9000 mm

Layer thickness

0 – 450 mm

Paving speed

0 – 12 m/min.

Travel speed

0 – 25 m/min.

Displacement

6 I

Machine weight

52000kg

Mechanical height adjustment

900 mm

Rated power

298,5 kW / 400 hp

Hydraulic height adjustment

900 mm

Concrete pavers are efficient machines used in modern construction projects for the production of monolithic concrete structures such as water channels. In particular, slipform concrete pavers are ideal for the continuous installation of structures such as concrete protection walls, curb profiles and water channels. These machines shape concrete in a specific mold, creating high quality and smooth surfaces. Concrete pavers play an important role in the construction of structures that perform critical functions such as water drainage, thus helping to manage debris such as rainwater and protect other structures.

Translated with DeepL.com (free version)

Saving water is essential to conserve limited water resources and ensure clean water for future generations. There are simple but effective ways to conserve water at home and in the garden. For example, repairing leaking faucets and pipes can significantly reduce water waste. Also, collecting rainwater and using it as needed can be a natural substitute for drinking water. Steps such as running machines at full capacity and taking short showers also contribute to saving water. These methods are effective for both protecting the environment and saving money on water bills.

Water channels are built for various purposes. Basically, they are used to widen waterways, direct the flow of water and facilitate transportation between regions. Historically, water canals served as trade routes, making it possible to exchange goods between different regions. They also have important functions such as irrigating agricultural land and supplying cities with drinking water. Today, water canals are of both economic and tourist importance, some of them are considered engineering marvels and are famous worldwide.