EU Stage 5 /

US EPA Tier 4f

1300

mm

The Most Profitable in its Sector

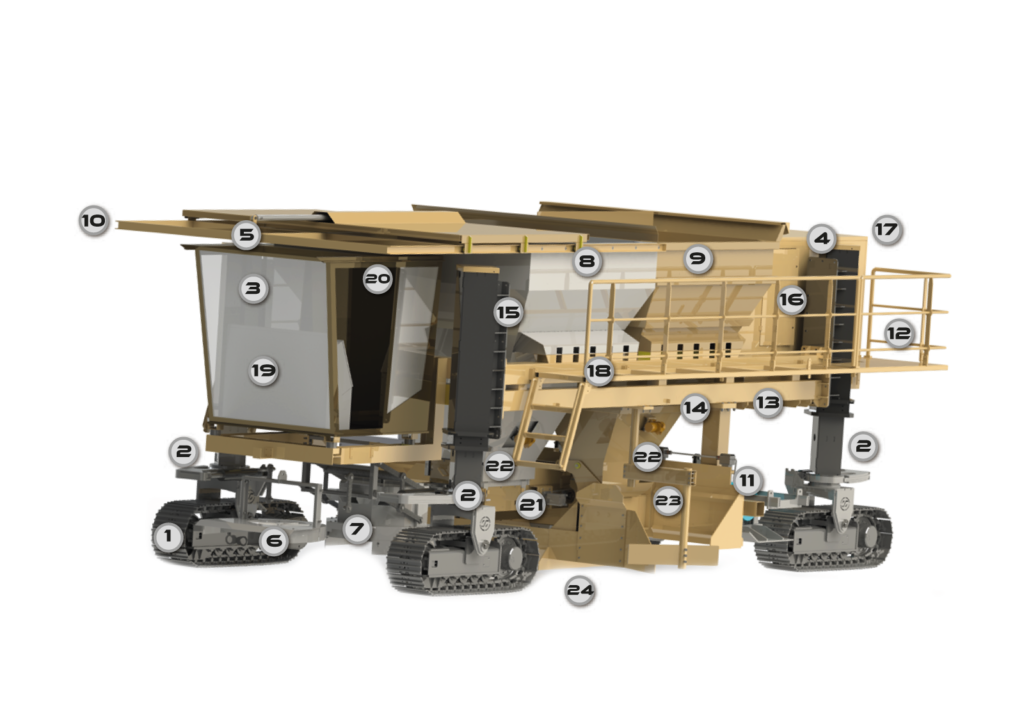

The Geometri ACDR X-4 Asphalt Core Dam Machine is a cutting-edge construction solution for building asphalt-core embankment dams. Unlike traditional clay-core dams, the ACDR X-4 uses a dense, flexible asphalt concrete core to create a watertight, durable barrier, offering superior impermeability, adaptability to ground movements, and long-term performance.

With advanced hydraulic automation, integrated compaction, and continuous paving capabilities, the ACDR X-4 ensures efficient, safe, and high-quality dam construction for large-scale infrastructure projects worldwide.

1. Simultaneous Layer Placement

The ACDR X-4 can place the asphalt core and adjacent transition zones in a single pass, similar to a 3D printing process, ensuring uniformity, precision, and time efficiency.

2. High Placement Speed

Modern technology allows the machine to construct asphalt cores at rates of up to 750 mm per day, significantly reducing construction timelines while maintaining structural integrity.

3. Integrated Compaction

Equipped with built-in vibratory and tamping plates, the ACDR X-4 compacts asphalt as it is laid, guaranteeing uniform density, high impermeability, and minimal cold joints.

4. Hydraulic Control & Automation

Fully hydraulic and automated, operators can precisely control layer thickness, width, slope, and compaction pressure from an advanced control panel. This ensures accurate placement even on steep slopes or irregular dam profiles.

5. Continuous Operation

The machine allows continuous asphalt placement along the dam’s length, reducing cold joints and increasing the watertight integrity of the structure.

The ACDR X-4 revolutionizes dam construction by combining:

With the Geometri ACDR X-4 Asphalt Core Dam Machine, you can build safer, more durable, and environmentally sustainable dams with confidence, speed, and precision.

Asphalt core dams, especially common in European countries and now being implemented in Turkey at the Kars Karakurt Dam and the Siirt Çetin Dam, are a type of dam. These dams prevent water leakage due to asphalt’s low permeability, resulting in less material usage and cost savings compared to clay core dams. Additionally, asphalt casting processes are resistant to challenging weather conditions and can continue even in the rain, reducing construction time loss. However, there are disadvantages such as the imported raw material for asphalt and the difficulty of casting during summer months. Nevertheless, cost and performance analyses of this dam type suggest that it could be a pioneer for future projects in Turkey

Asphalt core dams, especially common in European countries and now being implemented in Turkey at the Kars Karakurt Dam and the Siirt Çetin Dam, are a type of dam. These dams prevent water leakage due to asphalt’s low permeability, resulting in less material usage and cost savings compared to clay core dams. Additionally, asphalt casting processes are resistant to challenging weather conditions and can continue even in the rain, reducing construction time loss. However, there are disadvantages such as the imported raw material for asphalt and the difficulty of casting during summer months. Nevertheless, cost and performance analyses of this dam type suggest that it could be a pioneer for future projects in Turkey

One of the major advantages of these dams is that the permeability is almost zero and much less material is used compared to clay core dams. For example, a clay-core dam basically uses a 25-meter-wide core, whereas with asphalt-core dams this width can be reduced to just 2.05 meters. This results in significant savings in terms of both cost and time. In addition, asphalt paving operations are more resistant to harsher weather conditions and can continue even in light rain. This prevents extended working times and reduces extra costs.

Translated with DeepL.com (free version)

Asphalt core dams play an important role in managing and protecting water resources around the world. Such dams have excellent performance, particularly in terms of seepage control and stability. For example, a study at the Megech Dam in Ethiopia showed that asphalt concrete core dams are more effective in seepage control than clay core dams. In addition, the construction of asphalt core dams is less affected by weather conditions, reducing construction time and therefore costs. Countries such as Europe, Japan, China and Norway have built many such dams over the last 50 years, and now Brazil and Canada are building their first dams. Asphalt-core dams are important not only as an engineering achievement, but also for environmental sustainability; asphalt is a natural, non-toxic material that is ideal for drinking water reservoirs and does not harm the environment. These dams are particularly suitable for dams located in earthquake zones or on compressible soils, as the properties of asphalt concrete can be tailored to specific design criteria. Asphalt core dams offer an innovative and effective solution for managing and protecting water resources around the world.

Translated with DeepL.com (free version)