The Most Profitable in its Sector

EU Stage 3 /

US EPA Tier 3f

1000-12000

mm

0-450

mm

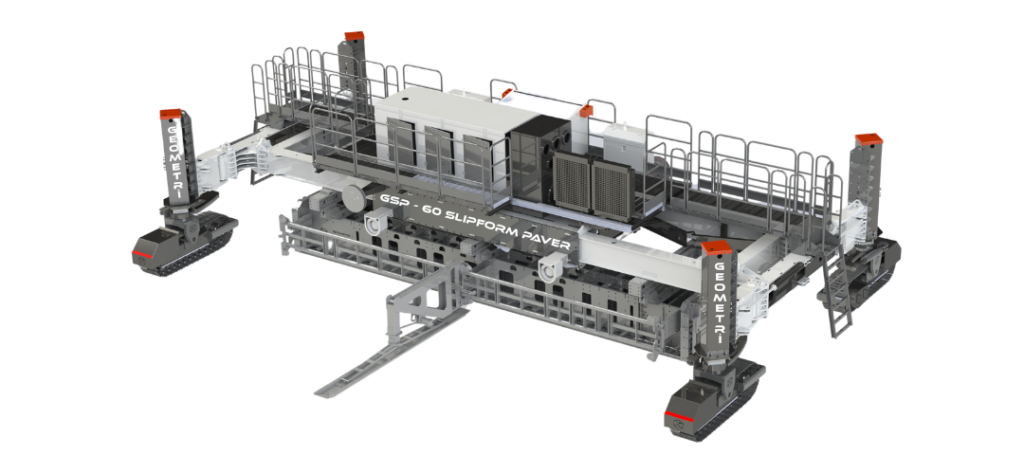

Make fast and cost-effective concrete paving. Concrete pavements are used for various projects such as highways, ports, main roads, airport runways, village roads, container storage areas or railway transport routes. These structures are exposed to a lot of stress due to heavy loads and high traffic. Concrete pavements are suitable for long-term loads. The increasing traffic volume worldwide also increases the demand for concrete pavements. For customers, smoothness, durability and timely completion of the project are very important. GEOMETRI slipform pavers, with working widths ranging from 1.0 m to 12.0 m, enable efficient production of concrete pavements. The machines are designed to meet both international standards and customers’ specific needs. GEOMETRI also offers the advantage of custom-made mold production for the project, which ensures precision.

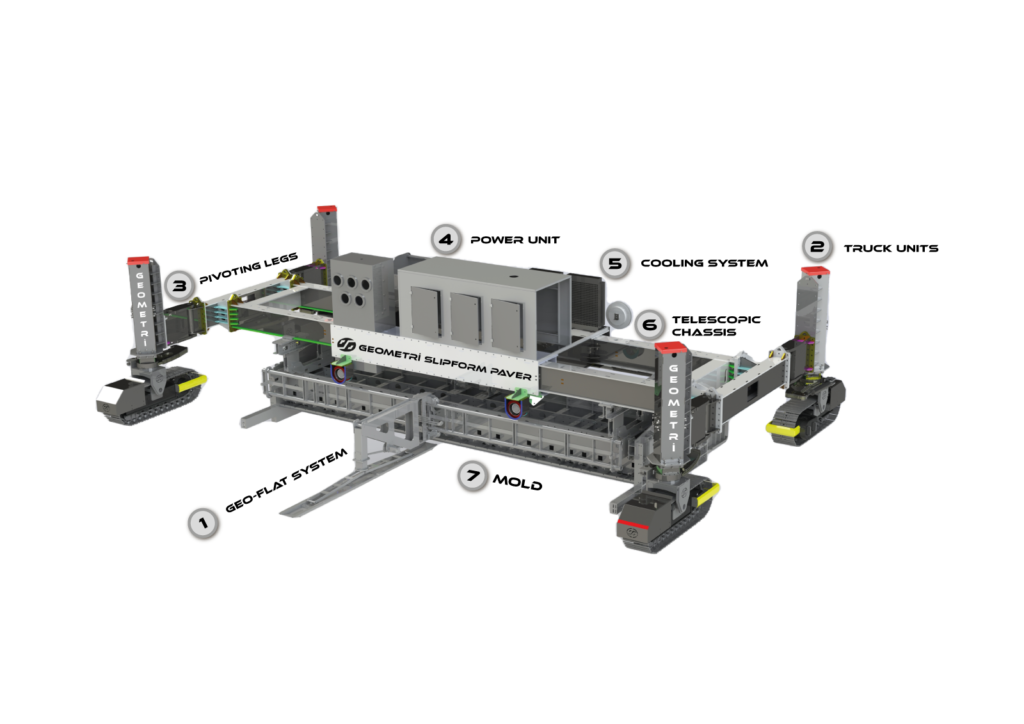

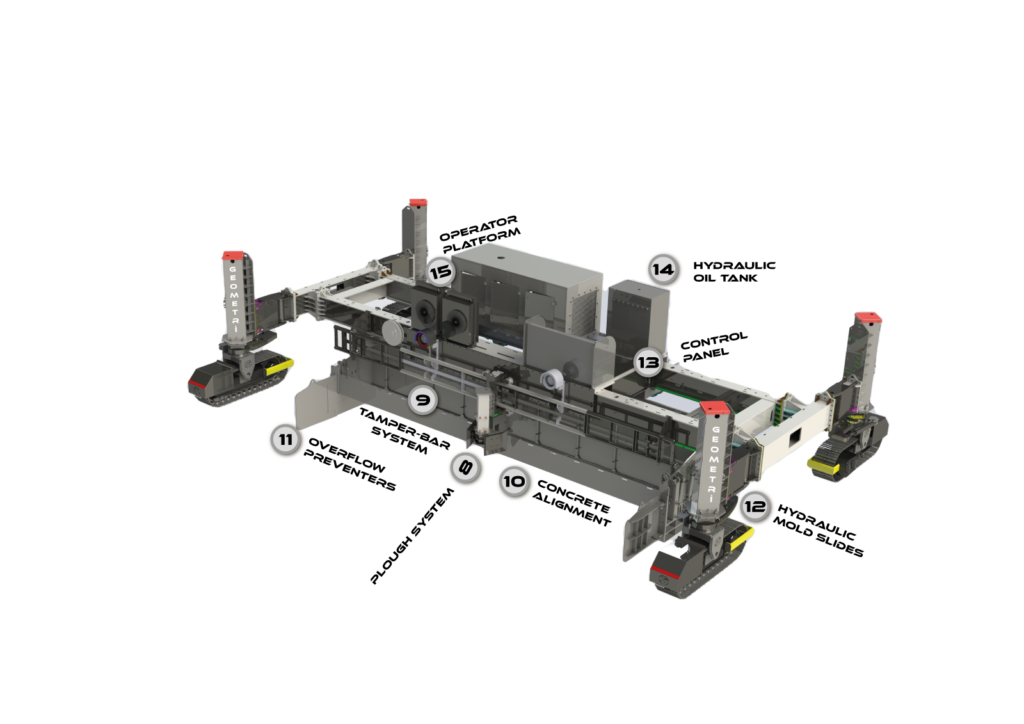

Placing the concrete between the tracks With the inset method, the concrete is either put right in front of the slipform paver or from the side, as needed a belt conveyor or a side feeder moves it to the front of the machine. A spreading auger or a plug system then spreads the concrete uniformly over the whole paving width. Built-in hydraulic vibrators consolidate the concrete evenly. Behind the plug is the pre-concrete alignment system. This system is hydraulically adjustable. This system keeps the concrete level in the chamber at a certain level and protects the selection area of the vibrators in the mold. The positions of the vibrator can be adjusted both in height and angle. There is a tamper-bar system behind the vibrators. It helps the concrete obtain a smooth surface by pushing large dirt inside the concrete. The inset slip formwork shapes the concrete pavement with a specific width and thickness as it advances. (Option)A dowel inserter can also be added to position the dowels properly .The specification is put into the concrete along the direction of movement. (Option)Middle or side tie bars can be placed across the road. The cross trowel screed(GEO-FLAT system) smooths the surface across the road. The “rubbing motion” makes a small ridge of concrete in front of the screed, which also ensures a high-quality surface. A longitudinal smoother can then be used to flatten the concrete ceiling.

Optimal flatness for a comfortable driving experience To achieve this goal, we use several technical improvements. The rigid, twist-free machine main frame helps a lot to make the concrete surface smooth. The inset slipforms also have a twist-free frame to avoid unevenness when the concrete quality changes. The heavy trowel screed makes the surface level without any bumps. The longitudinal smoother, made of high-grade material, then gives the final surface flatness with a shaking, combined back and forth and side to side movement. Additionally, the pressure of the smooter on the ground can be adjusted according to the consistency of the concrete

In Geometri Concrete Pavers, the vibrators can be adjusted on the control panel with the buttons the vibrator up and down and vibrator angles with hydraulically.

The chassis, which extends and contracts on both sides hydraulically, can easily enter narrow roads in variable concrete sizes and can be paved without losing time.

Thanks to the high-tech automation system, the operator only uses the start stop button in full automatic mode. Sensors constantly adjust the direction, level, slope, steering wheel of the machine very precisely and maintain the paving quality. Forward and backward speeds can be adjusted.

Exhaust emissions category

EU Stage 3 / US Tier 3

Number of track units

4

Paving width

1000 – 12000 mm

Layer thickness

0 – 450 mm

Paving speed

0 – 12 m/min.

Travel speed

0 – 25 m/min.

Displacement

6 I

Machine weight

55000 – 95000 kg

Mechanical height adjustment

900 mm

Rated power

343,3 kW / 460 HP

Hydraulic height adjustment

900 mm

The GSP120-X4 is engineered for a wide variety of concrete paving applications, delivering exceptional strength, geometry control, and surface quality in every scenario.

Precision in slope and thickness ensures perfectly leveled runways ready to handle heavy aircraft loads. The GSP120-X4 maintains flawless surface smoothness, integrates load-transfer joints, and allows custom texturing for anti-skid safety.

Ideal for high-load parking zones and maintenance hangars where resistance to fuel, oil, and mechanical stress is essential. The system enables drainage points, reinforced slab areas, and long-term durability with minimal cracking.

Handles concentrated loads from cranes, trailers, and heavy equipment. The GSP120-X4 produces high-density, uniformly compacted concrete with integrated expansion joints for heavy-duty logistics and port operations.

Perfect for rigid pavement on truck lanes and industrial roads. The machine ensures uniform slab thickness, precise edge control, and reduced joint frequency — extending pavement lifespan and cutting maintenance costs.

Ideal for regional connections and suburban infrastructure. The GSP120-X4 enables fast, continuous paving with accurate alignment and integrated drainage solutions, providing a durable, long-lasting roadway surface.

Ensures smooth grading, proper water drainage, and durable finishing. Adaptable molds allow creating curbs, parking stops, and textured pedestrian zones in one pass.

Creates safe, even surfaces with anti-slip finishing and smooth gradients. Suitable for urban cycling paths or light transport routes, combining durability with visual appeal.

Thanks to modular molds, the GSP120-X4 can form edges, shoulders, ducts, and utility channels, adapting perfectly to unique design requirements or integrated civil systems.

Airport runways are one of the most important elements of aviation infrastructure and are usually constructed using materials such as concrete or asphalt. Concrete runways are preferred at large airports due to their longevity and durability. For example, the runways of some major airports, such as Istanbul New Airport, are designed to have a high load capacity and are built using concrete. The surfaces of concrete runways are also provided with additional safety measures, such as transverse grooves to allow water to drain away, preventing slipping on wet surfaces. Asphalt runways are a shorter-lived alternative and are generally used at smaller airports. Both types of runways must provide a high level of straightness and good frictional behavior for safe landing and take-off of aircraft. The design and construction of airport runways is vital for aviation safety and requires specialized engineering knowledge.

Concrete highways are the preferred road construction material worldwide for their durability and longevity. The durability and low maintenance requirements of concrete make it an economical choice, especially for roads with high traffic loads. The history of concrete roads begins with the construction of Court Avenue in Ohio, USA in 1891. Today, approximately 47% of concrete roads are used in the USA, 40% in Belgium and 38% in Germany. In Turkey, the concrete road used on the road to the NATO radar base in Sinop in 1953 has been in service for more than 68 years without requiring maintenance. Concrete roads offer an environmentally friendly solution by saving 0.45 liters of fuel and reducing 1.2 kg of CO2 emissions per 100 kilometers. They also have additional advantages such as fire safety and increased visibility at night. For these reasons, concrete highways are an important infrastructure option in terms of both cost effectiveness and environmental sustainability.

The use of concrete roads offers significant environmental and economic advantages. Thanks to their rigid structure, concrete roads provide economic savings by reducing fuel consumption by an average of 0.45 liters per 100 kilometers. They require low maintenance over a long service life and have lower life cycle costs than alternative roads. Furthermore, within the framework of sustainable construction, the production and use of concrete roads promotes the efficient use of natural resources and increases respect for the environment. In this context, concrete roads are a sustainable solution for society and meet the key criteria of environment, economy and society.